Achieving Precision in Assembly Lines Through Custom Torque Program Development

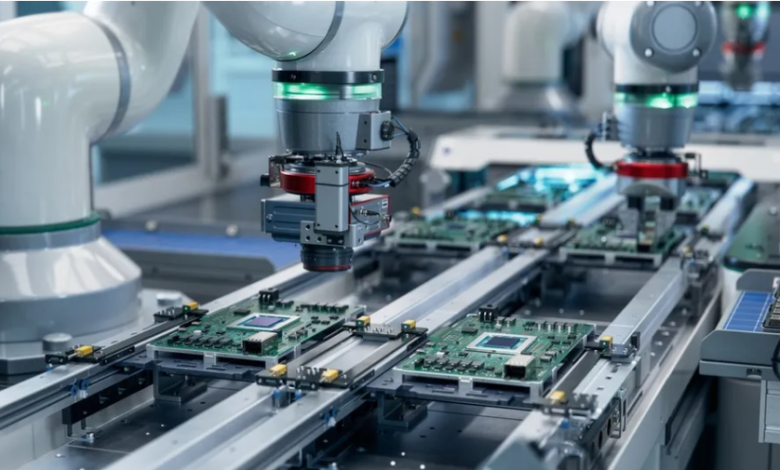

In industries where mechanical assembly plays a critical role, the tolerance for error is extremely limited. In sectors such as automotive supply chains, aerospace manufacturing, and industrial equipment production, the precise application of torque is essential for maintaining mechanical integrity, ensuring safety, and extending the lifespan of products. Custom torque program writing and development are therefore pivotal in securing these outcomes.

At Northern Lights Solutions, we specialize in advanced torque programming services that are meticulously designed to meet the diverse requirements of modern industry. But what precisely does “custom” torque program writing entail, and why is this specialization increasingly vital for contemporary manufacturers?

Understanding Industrial Custom Torque Program Development

Custom torque program development differs significantly from standard torque configurations that accompany OEM tools. It involves crafting detailed specifications tailored specifically to your components, materials, and tooling processes. This process transcends the mere definition of torque limits; it includes elements such as sequencing, speed control, angle measurement, multi-stage tightening, and adaptive fault detection.

Manufacturers engaged in assembling safety-critical components—such as suspension systems or pressure-sealed enclosures—require programs that are deeply integrated with PLCs, traceability databases, and factory automation systems. Such levels of precision and integration are unattainable with off-the-shelf software solutions.

See also: AI and Deepfake Technology: The Good, The Bad, and The Ugly

Addressing Non-Linear Torque Challenges

In real-world manufacturing environments, many fastening applications do not follow linear torque patterns. Factors such as part flex, gasket compression, and temperature variations can introduce unpredictability. Generic programs often lack the adaptive logic required to manage these variables effectively.

Through our custom torque program development, engineers at Northern Lights Solutions design logic paths that respond dynamically to real-time feedback. For example, in the assembly of industrial HVAC systems, it may be necessary to adjust torque values mid-sequence in response to component shifts or material expansion. Our programs are engineered to perform consistently and effectively under such conditions.

Supporting High-Mix, Low-Volume Manufacturing

For original equipment manufacturers (OEMs) operating within high-mix, low-volume environments, the agility of the assembly process can provide a significant competitive advantage. However, this flexibility should not come at the expense of precision. Custom torque program development enables teams to adapt assembly lines or product specifications swiftly while adhering strictly to torque requirements for each distinct assembly.

At Northern Lights Solutions, we develop modular and scalable torque programs, allowing manufacturers to alter configurations without necessitating an overhaul of the entire system. This capability supports prompt adaptation for custom orders or prototype runs while upholding stringent quality assurance standards.

Ensuring Data Integration and Traceability Compliance

Compliance with ISO, IATF, or medical manufacturing standards often hinges on the ability to document and trace every torque event, a task that cannot be managed effectively with standard programs alone.

By integrating custom torque logic with real-time data logging, barcode systems, and MES/ERP platforms, our clients gain comprehensive traceability for every torque cycle, encompassing tool identification, operator activity, and timestamps. This ensures compliance with audits and provides valuable insights into operational quality trends and tool wear.

Minimizing Downtime Through Predictive Control

Poorly written torque routines can result in frequent cycle interruptions, false rejections, and tool crashes, negatively affecting overall throughput. Our custom programming incorporates predictive logic to alleviate these concerns. For instance, real-time monitoring of inconsistent torque-angle relationships and automatic re-verification loops can maintain line productivity while ensuring quality standards are met.

This approach is particularly critical in continuous industrial operations, where unplanned downtime can lead to substantial costs—an issue that can be effectively mitigated through enhanced programming.

A Foundation for Precision

As industrial assembly processes evolve amid the challenges of automation, compliance, and cost management, custom torque program development is not merely a technical requirement; it serves as a strategic differentiator.

Northern Lights Solutions is dedicated to leading this transformation, empowering manufacturers across various sectors to harness the advantages of intelligent torque programming in meeting the demands of the future of production. We invite you to collaborate with us to strengthen every connection—both operationally and literally.