CNC Swiss Machining Services: Precision in Every Detail

CNC Swiss machining services have carved a niche for themselves in the world of manufacturing, thanks to their ability to produce parts with unparalleled precision and accuracy. These services are vital for industries that demand high-quality components with tight tolerances, such as aerospace, automotive, medical, and electronics. The unique combination of high precision, speed, and versatility has made CNC Swiss machining the go-to solution for producing small, intricate parts that would be challenging to create with conventional machining methods.

What is CNC Swiss Machining?

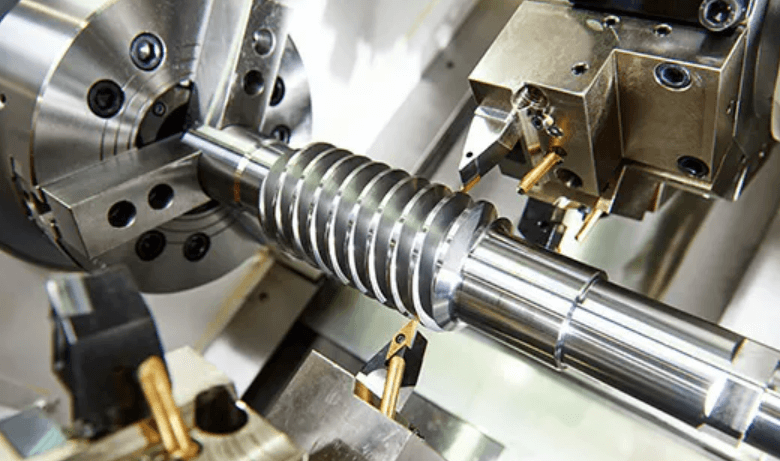

CNC Swiss machining refers to a highly advanced method of turning and milling that uses specialized CNC machines to produce complex parts. It involves a process where the material is held in a guide bushing, which provides support as the material is fed through the machine, allowing for the precise machining of small, detailed parts. The term “Swiss” comes from its origins in Switzerland, where this technology was developed to address the demand for producing precision parts.

What sets CNC Swiss machining apart is its capability to handle intricate and high-precision operations on small parts. The Swiss machine uses multiple axes and tooling options, allowing it to carry out multiple processes in a single setup, such as turning, drilling, tapping, and even milling. This combination of capabilities allows manufacturers to create parts with high efficiency and minimal error.

See also: AI and Deepfake Technology: The Good, The Bad, and The Ugly

Why Choose CNC Swiss Machining Services?

1. Precision and Accuracy

One of the most significant advantages of cnc swiss machining services is their ability to produce parts with extremely tight tolerances. This level of precision is crucial for industries that rely on components that must function perfectly and fit together seamlessly.

For example, in the medical industry, even a minor variation in the dimensions of a part can lead to functional failure, potentially causing harm to patients. Similarly, in aerospace, where safety is paramount, components like turbine blades or fasteners need to meet exact specifications to ensure the safety and efficiency of the systems they are used in. CNC Swiss machining meets these stringent demands, ensuring that parts are produced with the highest accuracy.

2. Ability to Handle Complex Geometries

CNC Swiss machining services are ideal for creating parts with complex geometries that would be challenging or impossible to produce using traditional machining methods. The multi-axis movement of the Swiss machine allows for the machining of intricate shapes and details in a single setup. Features like undercuts, grooves, and slots can be incorporated without the need for additional setups, making the process both faster and more efficient.

This ability to machine complex parts in a single pass saves both time and money while ensuring that each component meets the required specifications.

This versatility makes Swiss machining an attractive option for many industries.

For example, in the automotive industry, components like valve bodies, gears, and fuel injectors are often made from metals like aluminum and steel, which require the precision and durability that CNC Swiss machining offers. In contrast, the medical device industry frequently relies on materials like titanium for implants, as this material is biocompatible and offers high strength. Swiss machines can work with these materials and more, producing parts that meet the necessary mechanical and chemical properties.

4. Superior Surface Finish

The quality of the surface finish produced by CNC Swiss machining is another key benefit. Swiss machines use fine tools and precise control to produce smooth, polished surfaces, making them ideal for parts that require a high-quality finish. This is particularly important for industries such as medical devices, where a smooth surface is critical to ensure that components are safe for use in the human body.

In the automotive and aerospace industries, surface finish is equally important, as components like gears or fasteners must be smooth to ensure optimal performance and reduce friction. The superior finish that CNC Swiss machining services provide ensures that parts are both functional and aesthetically pleasing.

5. Reduced Lead Times and Increased Efficiency

CNC Swiss machining services are known for their speed and efficiency. Because Swiss machines are capable of performing multiple operations in a single setup, they reduce the need for part handling and multiple machine setups. This minimizes human error and makes the entire manufacturing process more efficient.

For industries that require high-volume production, Swiss machining services can help reduce lead times significantly. The automation involved in the process ensures that parts are produced quickly and accurately.

6. Consistent Quality

The automated nature of CNC Swiss machining ensures that every part produced is identical to the last. The high level of automation and the precise control offered by CNC machines help maintain consistent quality throughout the production process. This consistency is particularly important in industries like aerospace, where parts must meet stringent regulatory standards and pass rigorous quality assurance checks.

Moreover, because Swiss machining involves minimal human intervention, the risk of human error is reduced, ensuring that every component produced is of the highest quality.

Conclusion

CNC Swiss machining services offer a highly efficient, precise, and versatile solution for manufacturing small, intricate parts. The ability to handle complex geometries, tight tolerances, and a wide range of materials makes Swiss machining the go-to choice for industries like aerospace, medical devices, automotive, and electronics.

By providing superior surface finishes, reducing lead times, and maintaining consistent quality, CNC Swiss machining services have become a cornerstone of modern manufacturing. Whether you need to produce high-volume parts, custom prototypes, or highly detailed components, CNC Swiss machining ensures that your parts meet the highest standards of precision and performance.